Spider Hand Plate Arrangement Machine, also known as Spider Hand Plate Arrangement Machine, is an advanced automation equipment that combines bionic principles and parallel robot technology, and is mainly used to realize automatic plate loading and plate arrangement.

I. Definition and Overview

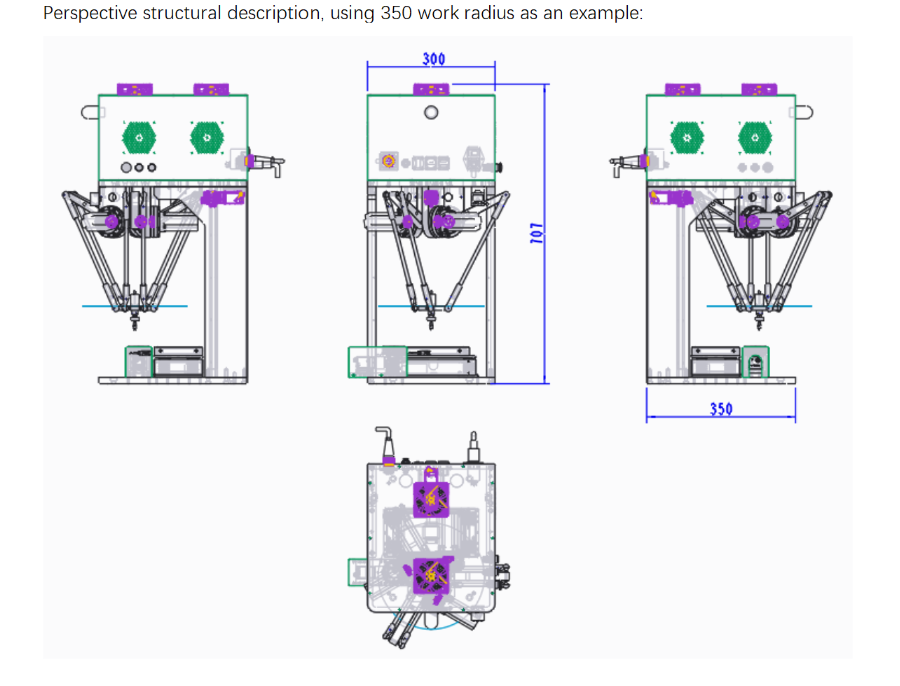

Spider Hand Plate Arrangement Machine is composed of multiple identical parallel mechanisms, which are inspired by the eight-legged structure of spiders. Each parallel mechanism is driven by a motor and realizes flexible movement in multiple directions through collaborative work. This design enables Spider Hand Plate Arrangement Machine to perform precise operations in a small space environment and meet complex plate loading requirements.

II. Features

High Precision and Flexibility: Spider Hand Plate Arrangement Machine has extremely high operating accuracy and flexibility, and can accurately grasp and place materials of various shapes, sizes and weights. Its multi-joint collaborative motion characteristics enable the robot to adapt to the plate loading requirements of different materials and realize fine operations.

Efficiency and Stability: Spider Hand Plate Arrangement Machine has high working efficiency and can process a large amount of materials in a short time. At the same time, its stable performance ensures the reliability of long-term continuous operation and reduces the failure rate and downtime.

Intelligence and automation: Many Spider Hand Plate Arrangement Machines are equipped with advanced visual inspection systems that can automatically identify information such as the location, shape, and quantity of materials. Based on this information, the robot can automatically adjust the loading strategy to improve loading efficiency and accuracy.

Strong adaptability: Spider Hand Plate Arrangement Machine is suitable for a variety of materials and loading requirements, and is widely used in food processing, medicine, logistics and other fields. Its flexible structure and programmability enable the robot to adapt to different working environments and task requirements.

III. Function

Improve production efficiency: Spider Hand Plate Arrangement Machine can automatically complete loading and arranging, greatly reducing the time and cost of manual operation. At the same time, its high-speed operation capability significantly improves production efficiency and meets the needs of large-scale production.

Ensure product quality: Due to the high operating accuracy of Spider Hand Plate Arrangement Machine, it can ensure that each material is placed on the plate according to uniform standards. This helps to reduce product defect rates, improve product quality and customer satisfaction.

Reduce labor costs: Spider Hand Plate Arrangement Machine can work continuously without rest, thereby reducing labor costs. At the same time, the consistency of robot operation also helps to reduce errors and waste caused by human factors.

Optimize the working environment: Using Spider Hand Plate Arrangement Machine can reduce the labor intensity of workers and improve the working environment. Workers can engage in easier and safer work, improve work efficiency and happiness.

With its high precision, high efficiency, intelligence and strong adaptability, Spider Hand Plate Arrangement Machine plays an important role in improving production efficiency, ensuring product quality, reducing labor costs and optimizing the working environment. With the continuous advancement of technology and the expansion of application fields, Spider Hand Plate Arrangement Machine will show its unique advantages in more fields.